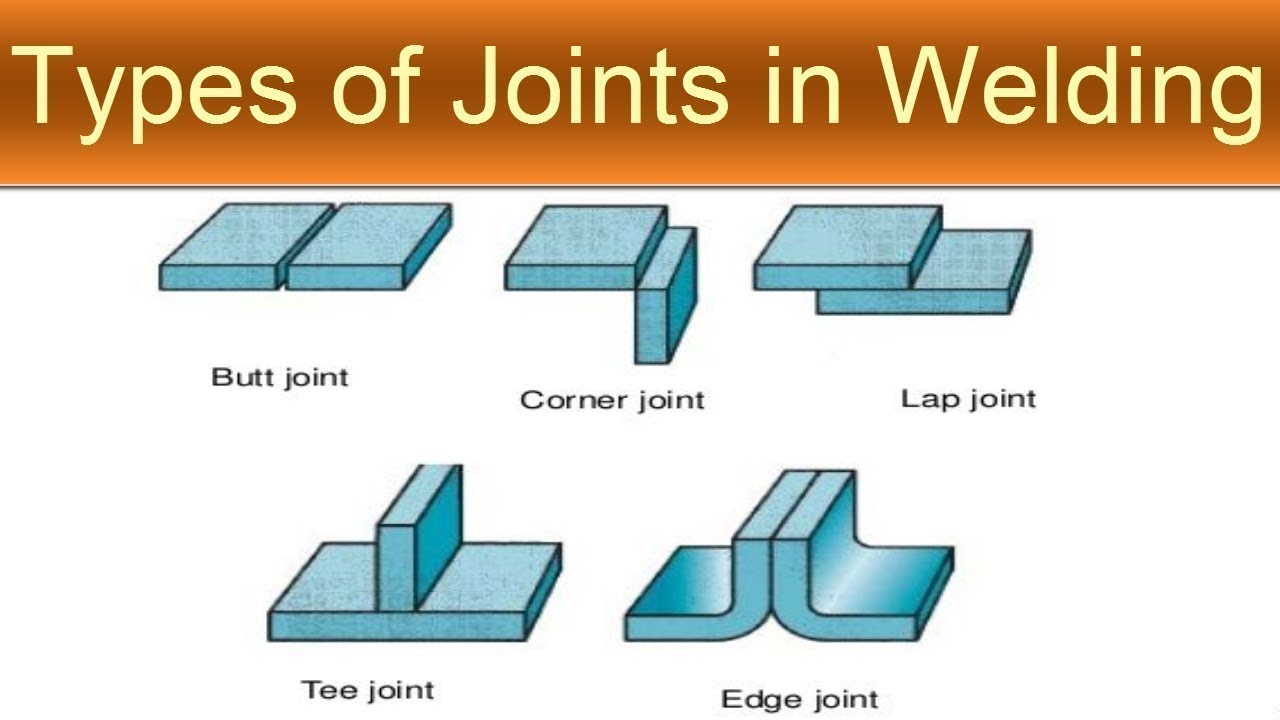

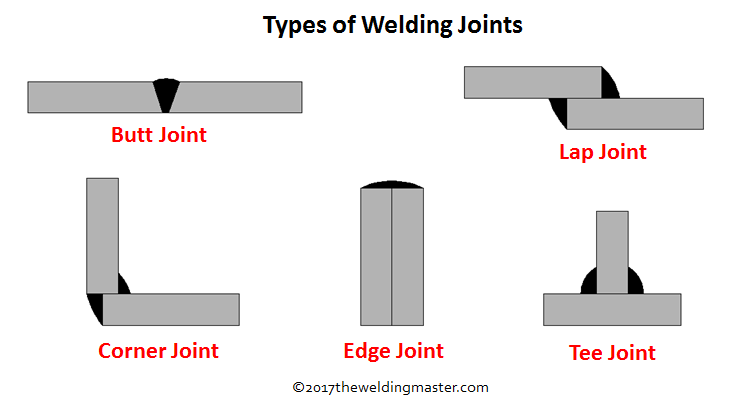

Explain Different Types of Welding Joints

When two round head pins are installed onto one plate the distance between two. We have writers who are well trained and experienced in different writing and referencing formats.

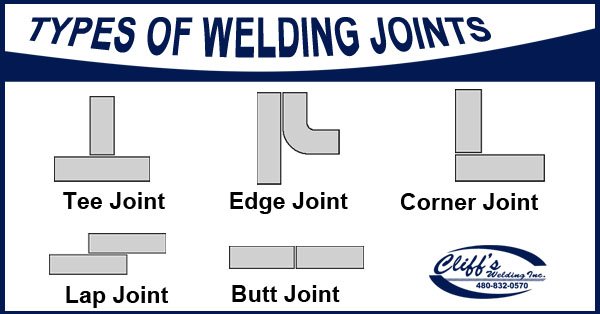

5 Types Of Welding Joints Cliff S Welding Mesa Az 480 832 0570

Resistance Welding and Types.

. Fillet weld is used to make corner joints lap joints and T joints. Contents show Resistance welding is a liquid state welding process in which a metal-to-metal joint is made in a liquid or molten state. We will explain the structure and show an example of how each style can be applied.

1Describe the complete step-by-step procedure of sand casting with neat sketches. Stop valves for flow isolation Check valves Flow regulating valves Control valves Safety relief valves Identify the common information identified on a valve name plate Explain the correct procedure for storing and handling of. The third party test results proved these types of wall systems perform exceptionally well in high-wind zone environments.

For plane and capsule geometry types PhysX provides helper functions to construct these transforms from common alternative. Plain carbon steel is the preferred material for the bulk about 90 of structural work. Here are the different weld types and the symbols that are used to depict them below.

Keep in mind that. STANDARD TYPES OF FLANGES. The Diamond Shape is a critical feature that helps with machining inaccuracies and smoother locating operation.

One assignment at a time we will help make your academic journey smoother. Or Write short notes on ADovetail joint B Lap joint 5. Achiever Papers is here to help you with citations and referencing.

The resistance welding is also known as the thermo-electric process in which heat is produced. A transform specifies the frame in which the geometry is interpreted. 2What is Die casting process and explain it.

For each welding process a welder has to be qualified separately. Z-type MCBs these are highly sensitive MCBs tripping when current exceeds the rated load by only two to three times. Explain about different types of pattern allowances.

To help you dial in your machine we will thoroughly explain each sets representation. The fillet weld symbols are usually triangular in the cross-section and its shape is usually not an isosceles or right triangle but it is a triangle either way. Suppose if a welder qualifies for SMAW then he shall be employed only for SMAW welding.

9Write the classification of Welding. They are a good choice for motors. Guidance as to procedure is given in AWS Standard D12-1.

In case if our requirement is MIG welding then the same welder will have to weld a different test coupon by MIG welding process then only he can be allowed for MIG welding. The type of flange to be used for a piping application depends mainly on the required strength for the flanged jointFlanges are used alternatively to welded connections to facilitate maintenance operations a flanged joint can be dismantled quickly and conveniently. Thermoplastics and polystyrene are commonly used for making patterns and Thermosetting plastics such as phenolics and epoxies are also used in a pattern.

Long Answer Type Questions. Are you having problems with citing sources. One of the most common pins is a stepped pin with either small or large head.

Explain the purpose of valves and where they are normally positioned in piping systems. Thermit welding is also used for joints that do not lend themselves to flash-butt welding for example at points and on bends. Identify the different types of joints and welds Explain the terms and symbols used for groove and fillet welds Describe the different welding positions Recognize the factors involved in the selection of joints.

Geometries are value types and inherit from a common base class PxGeometry. Identify different types of valves for the following functions. Joint Design Welding Symbols.

Type K MCBs these will trip when the current reaches eight to twelve times the recommended maximum. After completing this learning unit you should be able to. Each geometry class defines a volume or surface with a fixed position and orientation.

MIG welding process is one of the most straightforward processes to master but beginners often have issues getting the settings right. Different types of plastics are nowadays used in pattern because of their lighter weight strength and dimensionally stable and also for cheap in cost. A few more specialised MCB models are available.

4What are the different types of wood joints. They are used with. The stucco tests were performed in August 2011 at Smith-Emery Laboratories in Los Angeles CA following the ICCs Acceptance Criteria AC 191 Acceptance Criteria for Metal Plaster Bases Lath using Code-Compliant Lath fasteners studs.

Our professional writers are experienced in all formatting styles such as APA MLA Chicago Turabian and others. Reinforcing bar is welded with low hydrogen electrodes and with a preheat of 100250 C. EEP - Electrical engineering portal is study site specialized in LVMVHV substations energy power generation distribution transmission.

You can purchase the most expensive MIG welding machine on the market but the results may still vary. This means you can get your essay written well in any of. Different types of resistance welding explain with diagram and advantages applications and more.

Types Of Joints In Welding Youtube

Comments

Post a Comment